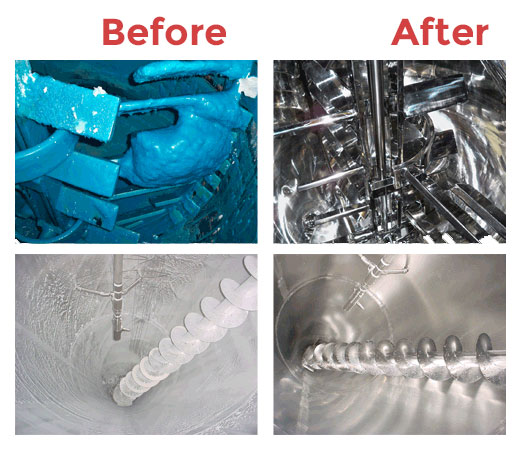

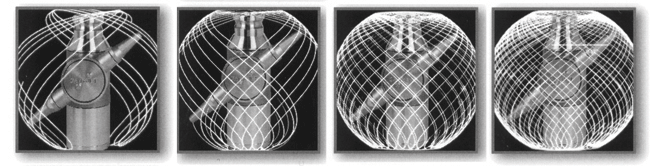

Gamajet’s rotary impingement tank cleaning machines combine pressure and flow to create high impact cleaning jets. Cleaning occurs at the point in which the concentrated stream impacts the surface. It is this impact and the tangential force that radiates from that point which blasts contaminants from the surface, scouring the tank interior. In conjunction with this impact, the Gamajet is engineered to rotate in a precise, repeatable and reliable, 360-degree pattern. This full-coverage, global indexing pattern ensures the entire tank interior is cleaned, every time. This combination of impact in a controlled indexing pattern results in an economic ideal, because impact is a one time investment; chemicals, temperature and time are continual, never-ending expenditures. With a short ROI, Gamajets impingement cleaning is GUARANTEED to positively impact the ultimate scorecard, your bottom line.

Customers that convert from other methods such as manual cleaning, rotary wetting, spray balls and fill and drain, typically realize a

Imagine your garden hose and a mud ridden fence. Without a nozzle, water falls from the hose. This water over time may “erode” away the mud on the fence, however if you were to slide your thumb over part of the opening, pressure builds behind the water and blasts away the mud. As it hits the fence, it radiates outward, maintaining low pressure and flow, but optimizing the impact or mechanical force. This is impingement. Impingement, is what sets Gamajet apart from other automated tank cleaners. Force. Gamajet machines are capable of creating up to 85lbs (39 kg) of force at a 25’ (7.5 m) distance with minimal pressure and flow. This is impossible with any other technology.

Imagine your garden hose and a mud ridden fence. Without a nozzle, water falls from the hose. This water over time may “erode” away the mud on the fence, however if you were to slide your thumb over part of the opening, pressure builds behind the water and blasts away the mud. As it hits the fence, it radiates outward, maintaining low pressure and flow, but optimizing the impact or mechanical force. This is impingement. Impingement, is what sets Gamajet apart from other automated tank cleaners. Force. Gamajet machines are capable of creating up to 85lbs (39 kg) of force at a 25’ (7.5 m) distance with minimal pressure and flow. This is impossible with any other technology. The speed of rotation is mechanically designed into the machine based on pressure and flow. Therefore if these factors (pressure and flow) remain constant, the cleaning pattern remains constant and the machine cleans in the exact same pattern at the exact same speed, every time. Wear parts have no effect on this process, making it 100% validatable.

The speed of rotation is mechanically designed into the machine based on pressure and flow. Therefore if these factors (pressure and flow) remain constant, the cleaning pattern remains constant and the machine cleans in the exact same pattern at the exact same speed, every time. Wear parts have no effect on this process, making it 100% validatable.